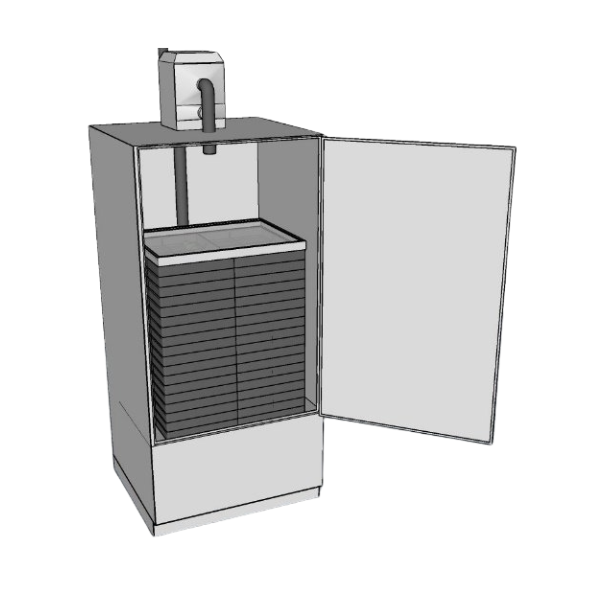

Drying Cabinet

For medical and recreational cannabis

Single, double or triple Drying Cabinet

Drying Cabinet

A Drying Cabinet is used to dry small volumes of cannabis buds of around 8 kg / 18 lbs. of dried cannabis per drying cycle. Drying cabinets with a double or triple capacity are available.

It is possible to control the drying cabinets with a control panel on the drying cabinets or with the ABC software on your phone, tablet or computer.

Sandwich units

Dried cannabis

Software

Test unit available

Efficiency

The temperature and humidity are controlled with the ABC-processor

Accessibility

The amount of airflow can be easiliy set and adjusted to the desired need

Development

Suitable for R&D purposes

Start Today

Our Cannabis Drying process is a seamless journey designed to deliver optimal results.

Consultation

Design and work

Complete & Maintenance

'Driven by Innovation'

Close

Close

Contact us for any questions!

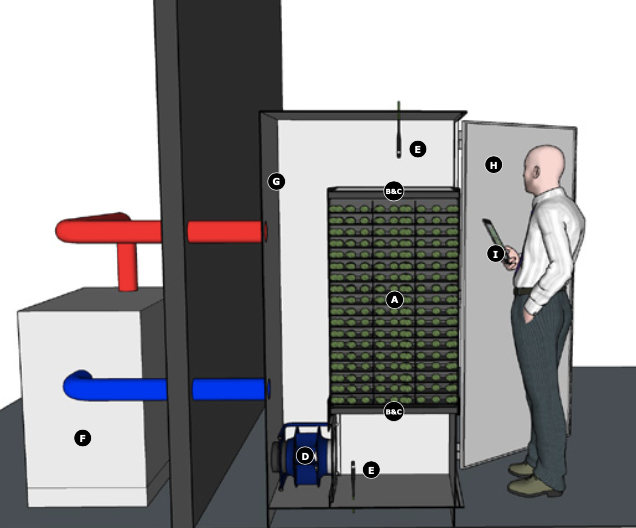

Components (single)

A. Canna-Trays

B. HEPA-Filter

C. Filter pads

D. Ventilator

E. Temperature + humidty sensors

F. Conditioning Unit

G. Isolation panels

H. Airtight door

I. ABC-software on a tablet

Components (double)

A. Canna-Trays

B. HEPA-Filter

C. Filter pads

D. Ventilator

E. Temperature + humidity sensors

F. Conditioning Unit

G. Isolation panels

H. Airtight door

I. ABC-software on a tablet

How it works

Stage 1

The ventilator (D) sucks the process air (1) through a set of Canna-Trays (A) and filters (B&C)

Stage 2

The air (2) dries the cannabis by adsorbing moisture from the cannabis

Stage 3

A part of this air (3) will circulate and enter the Canna-Trays (A) again. Another part of this air (4) flows via a tube (E) to the conditioning unit (F)

Stage 4

In the conditioning unit (F) water is extracted by adsorption and the air is brought to the desired temperature

Stage 5

Via tube (G) this controlled air (5) flows back into the drying cabinet and mixes with the process air (3)

Stage 6

The air (1) is at the desired temperature again and can start drying the cannabis further

Watch a video of how it works

Meet Nick

Nick Abbingh

After his dedication to fun during his Psychology studies in Amsterdam, he knew this would not be his occupation of choice. His interest was much greater in the new emerging market for Agratechniek called Cannabis-Drying.com. This brought the needed motivation to finish his studies and take a deep dive in the cannabis market. This motivation has never left, even though the boring years of covid made office life dreadful.

More info about Nick

Language

Response time

Check-in

Checkout

Cannabis-drying.com has exceeded our expectations with their top-quality drying equipment. Our clients love the results, and the team provided excellent support. We look forward to continuing our partnership!

Emily S.

Cannabis-drying.com has been a game-changer for our operations. Their drying solutions are top-notch, and our clients have noticed the difference in quality. Exceptional service and quick delivery every time!

Mark J.

We rely on cannabis-drying.com for all our drying needs. Their products are reliable and effective, leading to happier clients and better yields. The customer support team is fantastic. Highly recommend!

Lisa M.