50+

Years of Experience

Cannabis – Drying.com

Welcome to cannabis-drying.com, your go-to source for efficient drying solutions for both medical and recreational cannabis. We also offer rebuilds and extra’s to optimize your drying processes.

Parent company

About us

Over 50 years of experience providing high-end drying equipment

Cannabis-Drying.com stands at the forefront of drying technology. Our deep-rooted expertise and innovative approach allow us to provide unparalleled solutions tailored to your specific needs.

Cannabis drying solutions

products

The Drying Cabinet

The Drying Cabinet is used to dry small volumes of cannabis buds of around 8kg.

The Drying Cabinet

For individual drying of smaller quantities

Sandwich units

Dried Cannabis

Software

Medical

Optimize drying to preserve the potency and quality of medical cannabis.

Recreational

Maximize flavor and freshness with our drying equipment for recreational cannabis.

Mobile Drying Pallet

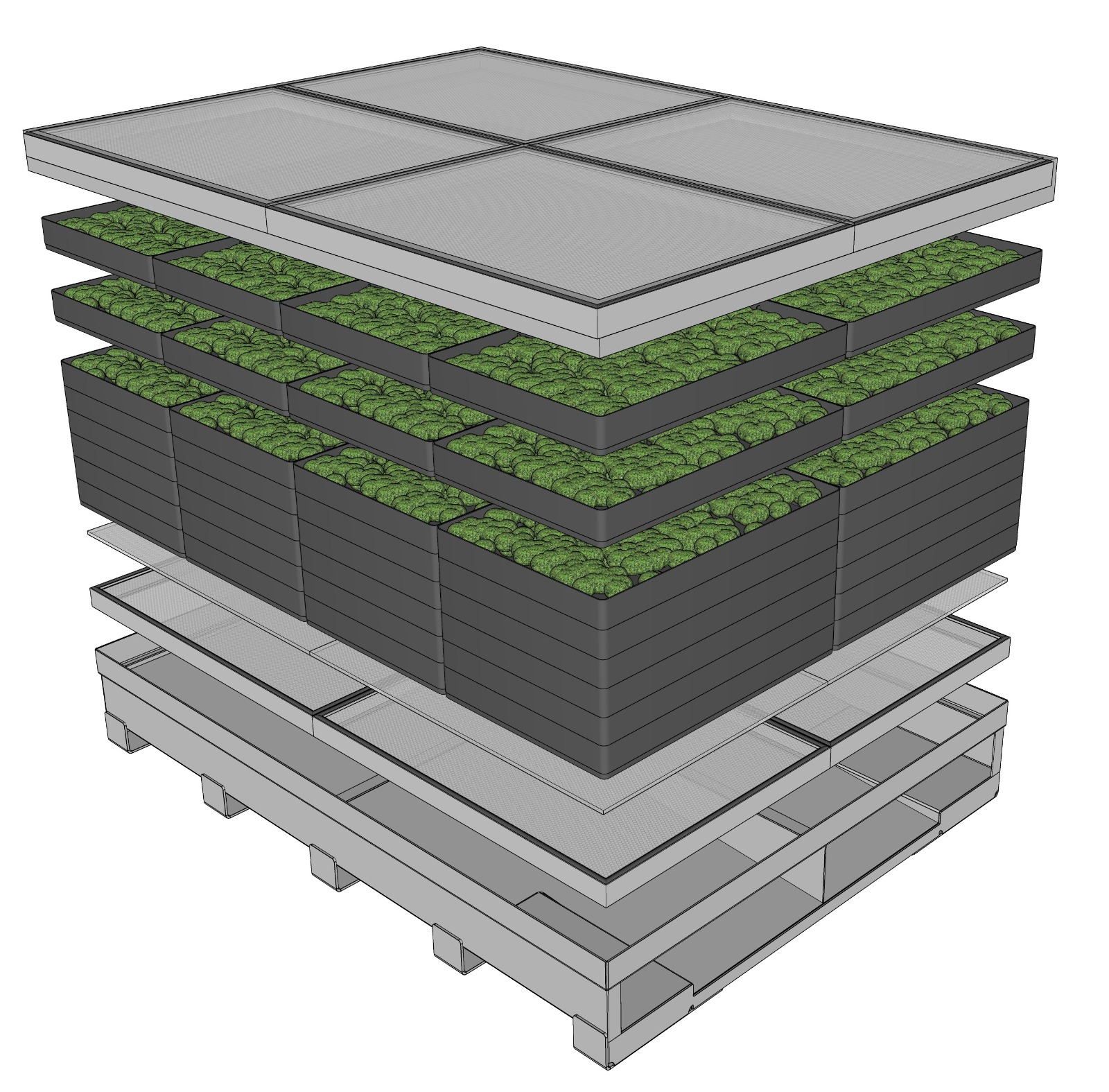

A Mobile Drying Pallet is used to dry large volumes of cannabis buds in anexisting or new drying room.

Mobile Drying Pallet

A Large number of mobile drying pallets can be place in a drying room

Sandwich units

Dried Cannabis

Software

Medical

Optimize drying to preserve the potency and quality of medical cannabis.

Recreational

Maximize flavor and freshness with our drying equipment for recreational cannabis.

Hang Drying Cell

To supply the demand of the entire market, we developed hang drying solutions as well.

Hang Drying Cell

The products goes straight from the growing room to the drying room

Bars or racks

Dried Cannabis

Software

Medical

Optimize drying to preserve the potency and quality of medical cannabis.

Recreational

Maximize flavor and freshness with our drying equipment for recreational cannabis.

Drying Cell

The Drying Cell is made easy handling of large quantities of cannabis.

Drying Cell

In the drying cells, the sandwich units are stacked on a ventilation pallet.

Sandwich units

Pallet per cell

Dried cannabis

Software

Recreational

Maximize flavor and freshness with our drying equipment for recreational cannabis.

Drying Tables

The Test Unit is designed to introduce the top-down drying method of cannabis to cultivators.

Drying Tables

For smaller quantities of Cannabis buds.

Sandwich units

Dried cannabis

Software

Rebuilds

The Rebuilds option offers eco-friendly, high-performance cannabis drying solutions with refurbished components for reliable, cost-effective results.

Tray Washer

Canna-Trays require cleaning, and efficient modular washers are available to minimize water and power use.

Tray Washer

Small and larger quantities

Capacity

Models

Extra

Our Extra category offers advanced solutions for tray washing and moisture analysis, ensuring optimal maintenance and product quality while enhancing efficiency.

The foundation of Cannabis-Drying.com

Top-down drying systems

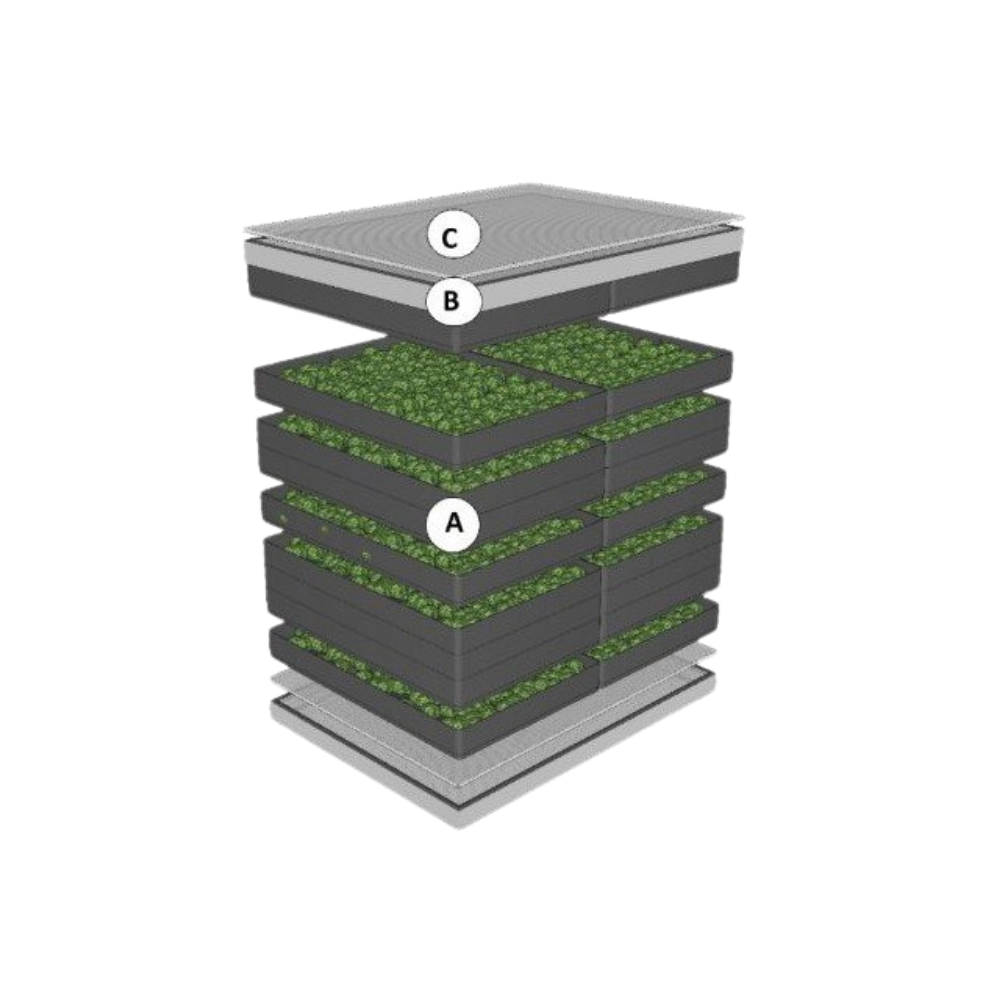

The foundation of our drying systems – Top-Down airflow drying method

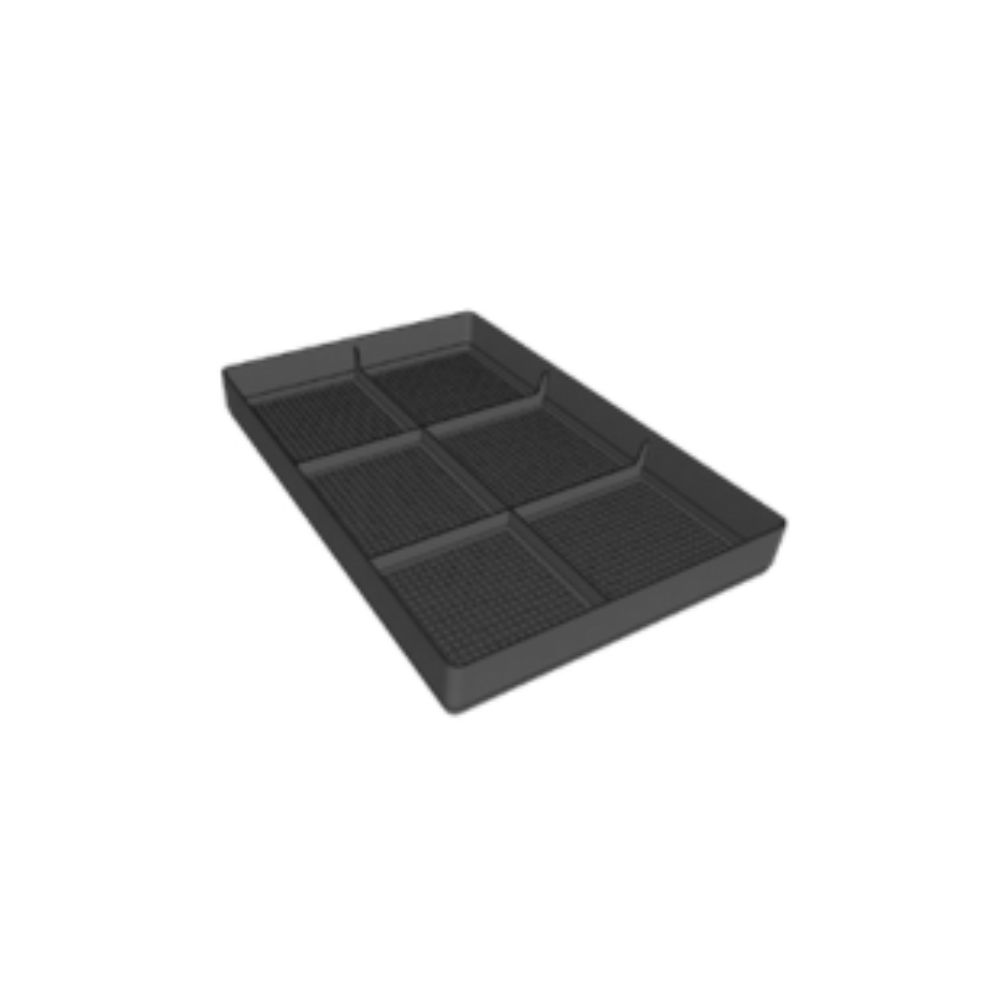

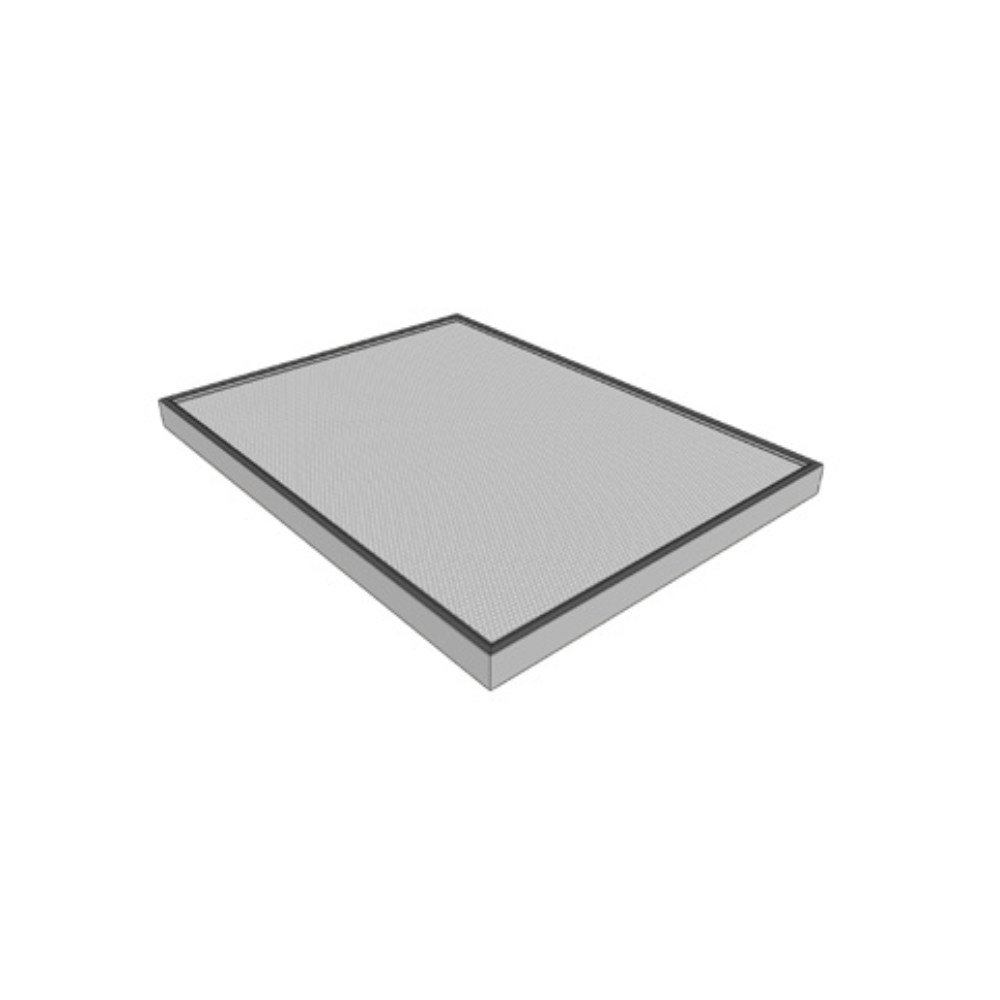

The foundation of our top-down drying systems is the Sandwich unit. It consists of two stacks of our Canna-trays and two types of filters on the bottom and on top. Altogether, this creates an airtight unit which is placed in our various systems. The Canna-trays can be filled with wet trimmed or bucked flowers.

The bucked flowers in the Canna-Trays consume 89% less space than the hanging plants in the drying racks.

Cannabis-Drying.com

Top-Down versus Hang Drying

Cannabis drying is a critical yet often overlooked process. While many facilities still dry cannabis by hanging stems upside down, Cannabis-Drying.com has developed a new system using Canna-Trays, where wet-trimmed flowers are dried with top-down air ventilation. When compared to traditional drying methods in the same room with controlled temperature and humidity, both systems showed minimal differences in terpene and cannabinoid content.

Active Installations

Continents

Years of Experience

Satisfied Customers