Drying Cell

Share

For recreational cannabis

Top-down drying system

Drying Cell

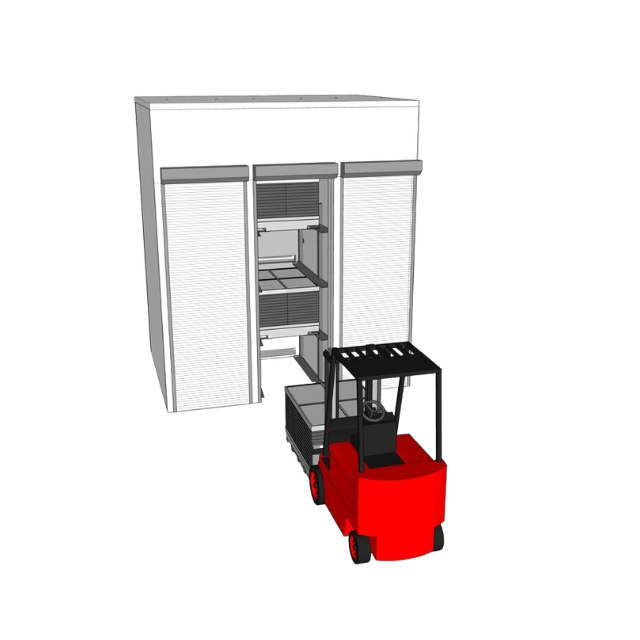

The drying cell operation features a forklift that transports a pallet sandwich, capable of drying 75-92 kg (165-203 lbs) of product per cycle. It is easily scalable and cleanable, with temperature control ranging from 14 to 28°C (57-82°F) and humidity levels adjustable between 30-90%. Airflow can be set to a desired volume.

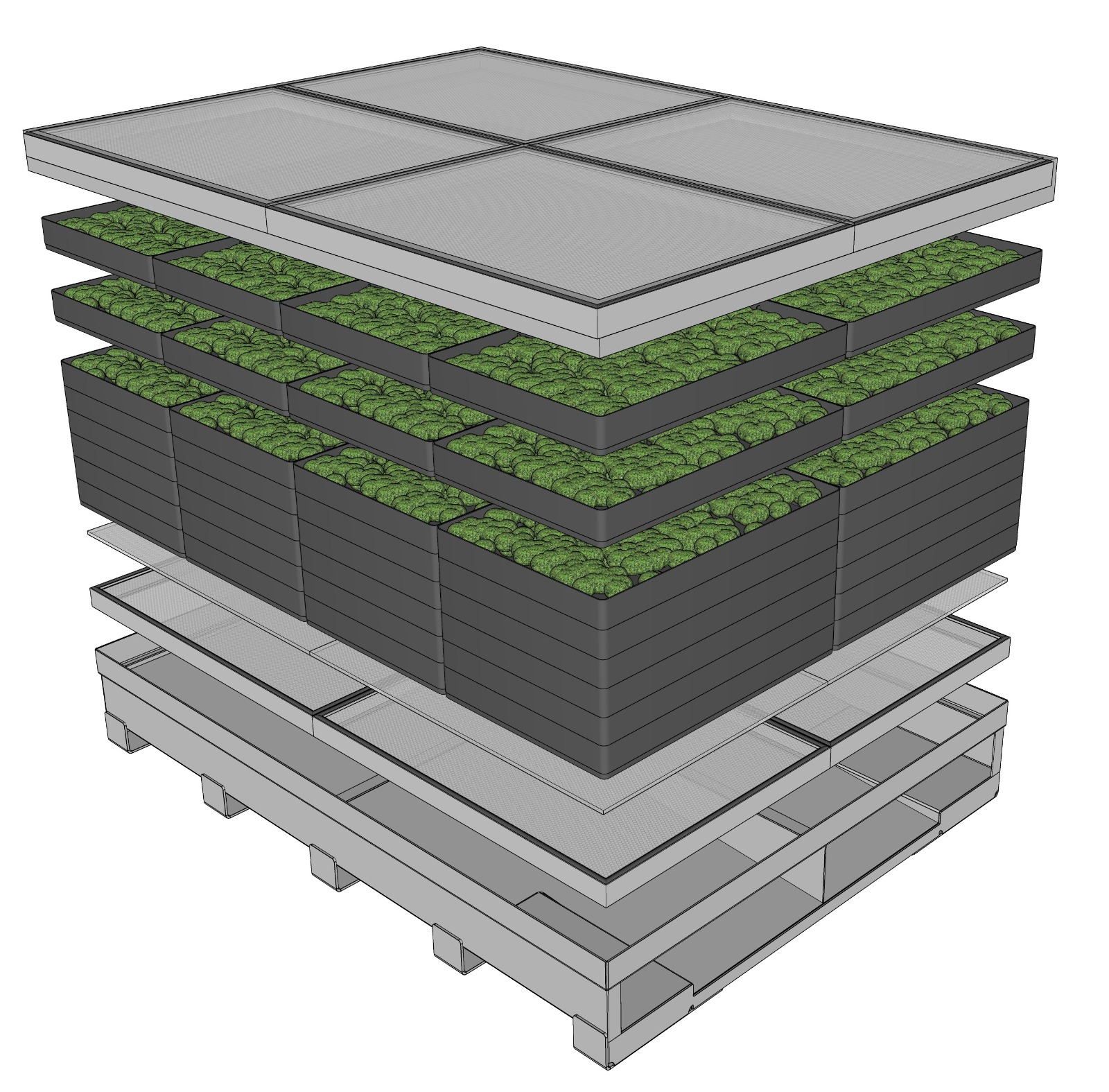

In the drying cells, the sandwich units are stacked on a ventilation pallet. The pallet with 4 sandwich units is called a Pallet-sandwich.

Sandwich units

Dried cannabis

Software

Test unit available

Start Today

Our Cannabis Drying process is a seamless journey designed to deliver optimal results.

Consultation

Design and work

Complete & Maintenance

'Driven by Innovation'

Close

Close

Contact us for any questions!

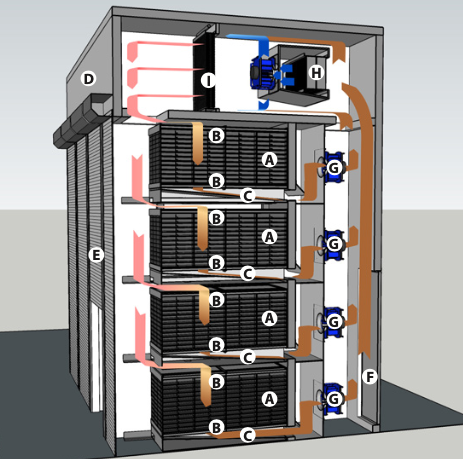

Components

A.

B.

C.

D.

E.

F.

G.

H.

I.

How is it used?

- A forklift driver, moving a Pallet-sandwich, approaches the drying cell

- On the ABC software the driver remotely (on a tablet) opens the roller shutter. Automatically, all devices in the drying cell turn off immediately

- The driver places the Pallet-sandwich in an empty space

- On the tablet, the driver closes the roller shutter of the drying cell. Automatically, all devices in the drying cell turn on.

- The manager controls the process from his/hers device (mobile phone, tablet, PC or screen on the switchboard).

How it works

Stage 1

The ventilator (G) sucks the process air (U) through the Canna-Trays (A), filters (B) and venitlation pallet (C)

Stage 2

The air dries the cannabis and the absolute humidity of the air increases

Stage 3

A part of the wet process air (W) flows through the condensation unit (H). In the condensation unit (H), the air cools down and water condensates

Stage 4

The cooler air (Z) blends with the process air (Y)

Stage 5

The blended air goes through the heater (I) where the air is again brought to the desired temperature

Watch a video of how it works

Meet Nick

Nick Abbingh

After his dedication to fun during his Psychology studies in Amsterdam, he knew this would not be his occupation of choice. His interest was much greater in the new emerging market for Agratechniek called Cannabis-Drying.com. This brought the needed motivation to finish his studies and take a deep dive in the cannabis market. This motivation has never left, even though the boring years of covid made office life dreadful.

More info about Nick

Language

Response time

Check-in

Checkout

Cannabis-drying.com has exceeded our expectations with their top-quality drying equipment. Our clients love the results, and the team provided excellent support. We look forward to continuing our partnership!

Emily S.

Cannabis-drying.com has been a game-changer for our operations. Their drying solutions are top-notch, and our clients have noticed the difference in quality. Exceptional service and quick delivery every time!

Mark J.

We rely on cannabis-drying.com for all our drying needs. Their products are reliable and effective, leading to happier clients and better yields. The customer support team is fantastic. Highly recommend!

Lisa M.